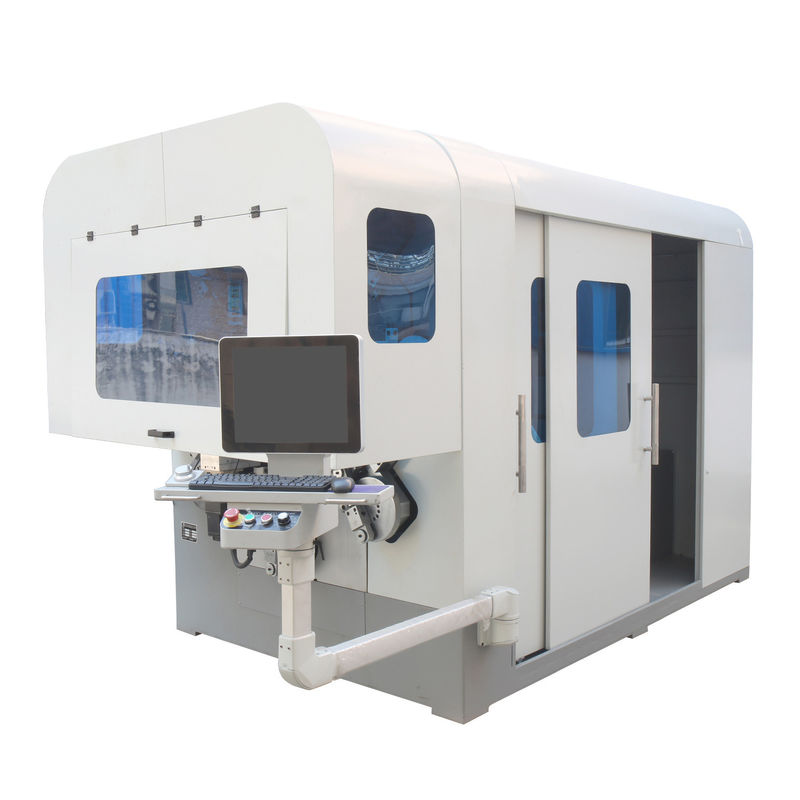

2.0 - 6.0mm Cam-less Sanyo Motor Suspension Spring Former Machine

The structure of the spring machine

Spring machinery is generally composed of a host, a control system, a motor power unit, auxiliary devices, and auxiliary equipment. The key is the control system, which has developed from the mechanical type controlled by electrical appliances to the CNC computerized spring machinery with electromechanical and optical integration. The control system is mainly composed of bus, CPU, power supply, memory, operation panel and display screen, position control unit, programmable controller logic control unit and data input/output interface. The main machine is also changed from the previous thick, black and heavy castings to alloy steel machine panels, which improves the mechanical strength and rigidity. The fully automatic closed gear transmission and lubrication make the spring mechanical precision and efficiency higher.

| Twelve Axes multi-functional spring machine |

| Model |

HYD-60T-12A |

| Axis Count |

12 axis |

| Wire Size Range |

low carbon steel:3-8mm |

| high-carbon steel:2-6mm |

| Lead rail |

distance of 130mm |

| Wire feeding count |

4 pairs |

| Max Feeding speed |

80m/min |

| Maximum error |

±0.1(length) |

| Control system+decoiler |

1 set |

| Servo motor power |

49.7KW |

| Reducer |

11pcs |

| Minimum length of angel |

4 times wire diameter |

| Machine size |

2600*1400*2050mm |

| Machine weight |

4500kg |

Our Services

1 Professional and patient consulting service to help you find the suitable solution.

2 Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3 Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4 Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5 Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6 For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7 For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that.

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

6. Q: How to contact us?

A: Web: www.cnc-springmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!