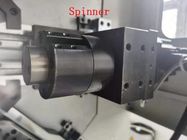

2 - 6mm Camless Spring Forming Machine NSK Bearing Spring Machine CNC Wire Rotating Machine

Introduction

Spring machinery is a general term for all kinds of machinery that produce various springs. There are manual and automatic.

The domestic spring machinery is widely used in each industry, sold around the world, and the market share is relatively large.

After 2000, computer-controlled automatic spring machinery has gradually become the first choice of spring companies, it is

suitable for developing of modern industry. Especially, camless spring machine with wire rotation is good at making complex,

different shapes of springs. It is easy to operate, commissioning and high efficient.

Machine characteristics:

1. The use of connecting rod armless design, single-axis servo motor independent control, easy operation, special-shaped

springs can reduce the adjustment time by placing the tooling angle, and improve production efficiency.

2. Adopting Taiwan roller guide rail, which has good wear resistance and can maintain precision for a long time.

3. Servo shear design, cut directly after forming, process longer products, reduce the impact force of cutting on the mandrel,

and protect the cutter and the machine.

4. Taiwan control system. It can more effectively ensure the synchronization between the machine and the computer.

5. The wire transfer motor is separated from the wire feed box, which reduces the load of the wire feed box, increases the wire

transfer angle, and effectively guarantees the accuracy of the wire feed transfer.

Data sheet

| Twelve axes mufti-functional spring machine |

| Model |

HYD-60T-12A |

| Axis Count |

12 axis |

| Wire Size Range |

low carbon steel:3-8mm |

| high-carbon steel:2-6mm |

| Lead rail stroke |

distance of 200mm |

| Wire feeding wheel groups |

4 |

| Max Feeding speed |

80m/min |

| Maximum error |

±0.1(length) |

| Control system+decoiler |

1 set |

| Servo motor power |

51.2KW |

| Reducer |

11pcs |

| Minimum length of angel |

4 times wire diameter |

| Machine size |

4200*2100*2350mm |

| Machine weight |

6000kg |

1. Length 4200mm

2. Inner height is 2100mm.

3. Space inside is large enough to stand a few people.

4. It is fixed with sliding doors, will not take up space.

5. Protective cover is for reducing noise, protecting production.

6. Equipped with transformer that is suitable for many different voltage scenarios.

Packing and deliverying

Packing: wooden case

Deliverying: within 45-60 days after down payment

Machine Structure

Spring machinery is generally composed of a host, a control system, a motor power unit, auxiliary devices, and auxiliary

equipment. The key is the control system, which has developed from the mechanical type controlled by electrical appliances to

the CNC computerized spring machinery with electromechanical and optical integration. The control system is mainly

composed of bus, CPU, power supply, memory, operation panel and display screen, position control unit, programmable

controller logic control unit and data input/output interface. The main machine is also changed from the previous thick, black

and heavy castings to alloy steel machine panels, which improves the mechanical strength and rigidity. The fully automatic

closed gear transmission and lubrication make the spring mechanical precision and efficiency higher.

The spring machine includes the machine body, operation panel, feed mechanism, tool holder (mechanical arm), hydraulic and

other mechanical components. It is a mechanical part used to complete all kinds of spring wire processing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!